In the intricate world of oil and gas drilling, ensuring the integrity and stability of the wellbore is paramount. Among the various tools employed to achieve this, stop collars play a crucial role in maintaining the position of casing accessories, such as centralizers and cement baskets, during the cementing process. This comprehensive guide delves into the types, functions, and selection criteria of stop collars, providing valuable insights for professionals in the field.

Stop collars are mechanical devices installed on casing strings to prevent the axial movement of casing accessories. By securing centralizers and other tools in place, stop collars ensure optimal spacing between the casing and the wellbore, facilitating effective cement placement and zonal isolation. Their application is critical in achieving a successful primary cementing operation, which is fundamental to the structural integrity of the well.

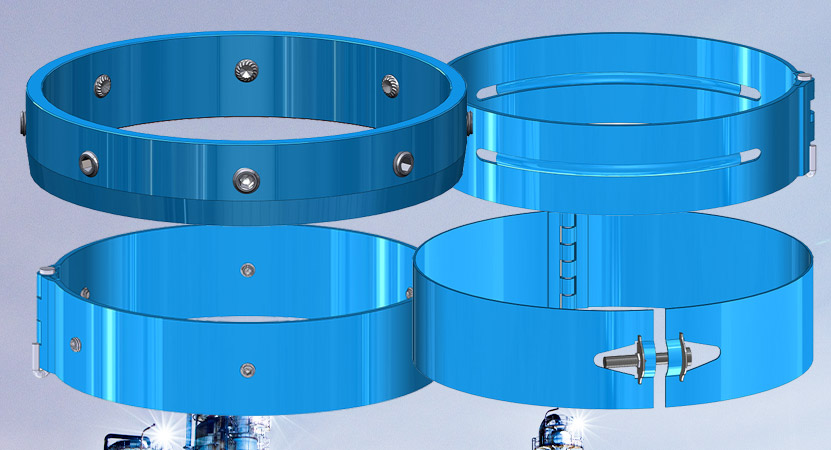

Slip-On Set Screw Stop Collar: This type is a single-piece collar that slides onto the casing and is secured using set screws. It is ideal for applications where high axial loads are expected and where annular clearance is limited. The slip-on design allows for easy installation, and the set screws provide a strong grip on the casing.

Features:

Hinged Bolted Stop Collar: Comprising two hinged halves secured by bolts, this collar is designed for quick installation without the need to slide over the casing end. It is especially useful in situations where the casing string is already assembled.

Features:

Hinged Set Screw Stop Collar: Similar to the hinged bolted version, this collar uses set screws instead of bolts for securing. It offers a balance between ease of installation and holding strength, making it suitable for various wellbore conditions.

Features:

Hinged Spiral Nail Stop Collar: This collar employs spiral nails driven into the casing to secure the collar in place. The design ensures a robust grip, making it suitable for high-torque and high-load applications.

Features:

Cable Wall Cleaner: While not a traditional stop collar, the cable wall cleaner serves a similar purpose by aiding in the removal of mud cake and debris from the wellbore wall. It enhances the effectiveness of cementing by ensuring a clean surface for cement bonding.

Features:

Wire Scratcher: Similar to the cable wall cleaner, the wire scratcher is designed to remove mud cake from the wellbore wall. It consists of wire bristles that scrape the wall as the casing is run into the hole, promoting better cement bonding.

Features:

When choosing the appropriate stop collar for a specific application, consider the following factors:

Stop collars are essential components in oil and gas drilling operations, ensuring the proper placement and stability of casing accessories during cementing. By understanding the various types of stop collars and their specific applications, drilling professionals can make informed decisions to enhance well integrity and operational efficiency. Selecting the right stop collar involves careful consideration of wellbore conditions, casing specifications, and operational requirements. With the appropriate choice, stop collars contribute significantly to the success of cementing operations and the overall safety of drilling activities.

Looking for reliable, API-compliant stop collars for your next cementing operation?

At Emson Oil Tools, we offer a wide range of premium-quality stop collars including Slip-On Set Screw, Hinged Bolted, Hinged Spiral Nail, and more — designed to meet the most demanding wellbore conditions.

👉 Explore Our Stop Collars

📩 Contact us today for technical support, custom orders, or bulk inquiries.

Copyright © Emson Oil Tools. All Right Reserved. | Privacy Policy | Terms & Conditions