In the intricate process of oil and gas drilling, ensuring the integrity of the wellbore is paramount. One critical component that plays a vital role in this is the solid body centralizer. This article delves into the various types of solid body centralizers, their applications, functions, materials, buyer considerations, and frequently asked questions related to their use in cementing operations.

A solid body centralizer is a mechanical device used in the oil and gas industry to ensure the proper placement of casing within the wellbore. Unlike bow-spring centralizers, solid body centralizers are constructed from a single piece of material, providing robust support and maintaining the casing’s central position during cementing operations. This centralization is crucial for achieving uniform cement distribution around the casing, which enhances zonal isolation and well integrity.

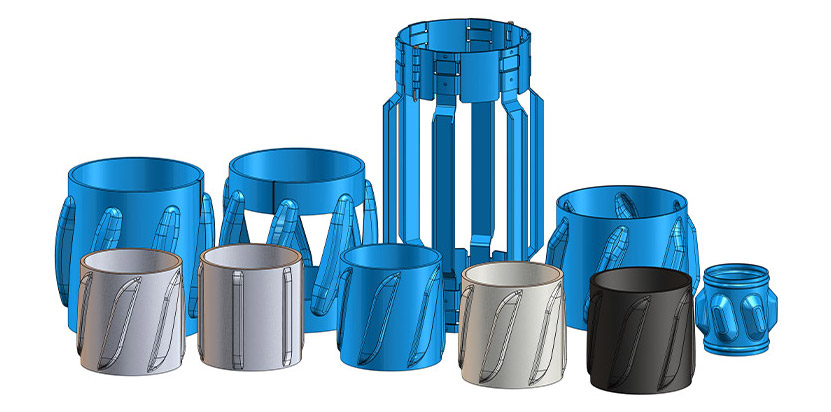

Roller Centralizer – Low Torque Type: Designed to reduce torque during casing operations, these centralizers feature rollers that convert sliding friction into rolling friction. This design is particularly beneficial in deviated and horizontal wells, where torque reduction is essential for efficient casing deployment.

Roller Centralizer – Low Drag Type: These centralizers are engineered to minimize drag forces encountered during casing running. The horizontal roller arrangement significantly reduces the dragging force, enabling smoother casing movement in extended-reach wells.

Slip-On Welded Positive Spirolizer: This robust tool features a steel construction with spiral fins welded onto a one-piece rolled end collar. It’s optimized for horizontal and deviated wells, ensuring smooth operations in low-side boreholes. The spiral design minimizes drag forces and enhances fluid turbulence for better cement bonding.

Aluminum Straight Blade Solid Rigid Centralizer: Constructed from high-tensile cast aluminum, this centralizer offers excellent corrosion and impact resistance. The straight blade design with beveled vane ends allows seamless entry into restrictions and minimizes drag during operations, making it suitable for challenging well conditions.

Carbon Steel Spiral Blade Solid Rigid Centralizer: Made from durable carbon steel, this centralizer features spiral blades that promote turbulence in the cement slurry, improving mud displacement and cement bonding. It’s suitable for both open-hole and cased-hole applications in various well orientations.

Slip-On Heavy Duty Straight Spirolizer: Designed for demanding wellbore conditions, this centralizer provides superior casing centralization with its durable steel construction and straight fins. It’s effective in vertical, deviated, and horizontal wells, ensuring reliable performance in challenging environments.

Slip-On Welded Heavy Duty Positive Spirolizer: Engineered for extreme load conditions in highly deviated horizontal wells, this centralizer features symmetrical spiral fins securely welded to a one-piece rolled-formed sleeve. Its robust construction ensures superior toughness and durability.

Slip-On Stand-Off Band: This accessory provides additional standoff between the casing and wellbore wall, enhancing cementing efficiency. It’s typically used in conjunction with other centralizers to achieve optimal casing centralization.

Heavy Duty Stand-Off Band: Designed for heavy-duty applications, this stand-off band offers increased strength and durability. It’s suitable for challenging well conditions where additional support is required to maintain casing centralization.

Zinc Spiral Blade Solid Rigid Centralizer: Constructed from zinc, this centralizer features spiral blades that enhance fluid turbulence, promoting better cement bonding. Its design ensures smooth casing movement and reduces the risk of differential sticking.

Aluminum Spiral Blade Solid Rigid Centralizer: This centralizer combines the lightweight properties of aluminum with the efficiency of spiral blades. It’s ideal for high-deviation and horizontal wells, where enhanced fluid flow and reduced drag are essential.

Roller Centralizer – Low Torque & Low Drag Type: This hybrid design incorporates features from both low torque and low drag centralizers. It effectively reduces both torque and drag forces, ensuring smooth casing deployment in complex well trajectories.

Solid body centralizers are typically constructed from materials such as:

The choice of material depends on the specific well conditions, including temperature, pressure, and corrosive environments.

When selecting a solid body centralizer, consider the following factors:

Q1: What is the primary function of a solid body centralizer?

A solid body centralizer ensures the casing is centered in the wellbore, promoting uniform cement distribution and enhancing zonal isolation.

Q2: How does a roller centralizer differ from other types?

Roller centralizers incorporate rollers that convert sliding friction into rolling friction, reducing torque and drag during casing operations.

Q3: When should I use a spiral blade centralizer?

Spiral blade centralizers are ideal for wells where enhanced fluid turbulence is required to improve cement bonding and mud displacement.

Q4: Are aluminum centralizers suitable for all well conditions?

Aluminum centralizers are lightweight and corrosion-resistant, making them suitable for many applications. However, for HPHT wells, materials like carbon steel may be more appropriate.

Q5: Can I use multiple types of centralizers in a single well?

Yes, combining different centralizer types can optimize casing centralization and cementing efficiency, especially in complex well trajectories

Solid body centralizers play a crucial role in ensuring the success of cementing operations in the oil and gas industry. By understanding the various types, materials, and applications, operators can make informed decisions to enhance well integrity and operational efficiency.

Looking for reliable, API-certified solid body centralizers for your next drilling project?

At Emson Oil Tools, we offer a comprehensive range of solid body centralizers, including roller centralizers, spirolizers, and stand-off bands, engineered for both onshore and offshore environments.

👉 Explore Our Solid Body Centralizers

📩 Contact us today for custom solutions or bulk inquiries.

Copyright © Emson Oil Tools. All Right Reserved. | Privacy Policy | Terms & Conditions