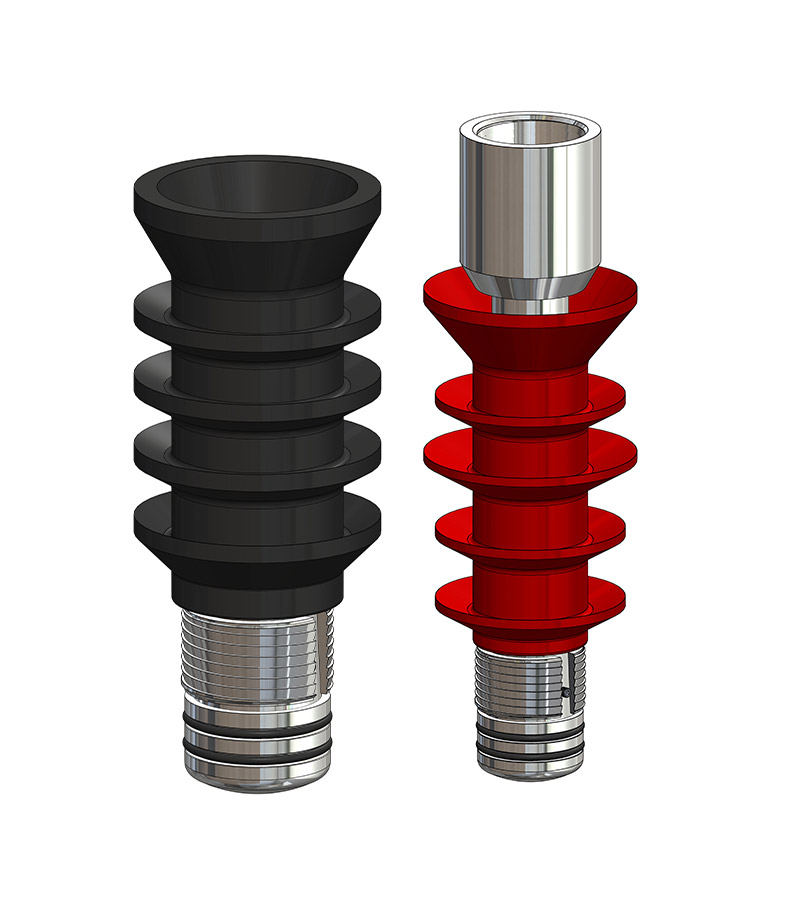

Cementing plugs are essential components in wellbore cementing operations, used to separate drilling fluids from cement slurry and ensure clean displacement. At Emson Oil Tools, we offer a full range of high-performance cementing plugs, including Latch-in Cement Plugs, Non-Rotating Cement Plugs, and Conventional Cement Plugs, available in top and bottom plug configurations.

Our API-compliant cementing plugs are designed to withstand high pressures, prevent fluid contamination, and improve well integrity. The non-rotating plugs reduce drill-out time, while latch-in plugs ensure precise placement and secure engagement with stab-in float collars.

Whether you need drillable PDC plugs for vertical, deviated, or horizontal wells, Emson Oil Tools delivers reliable and cost-effective solutions trusted by operators worldwide. As a leading cementing plug manufacturer and exporter in India, we focus on product quality, durability, and operational efficiency in challenging environments.

Frequently Asked Questions (Faqs)

Q 1: What are cementing plugs used for in oil and gas wells?

Cementing plugs are used to separate drilling fluid and cement slurry, ensuring clean displacement and effective zonal isolation.

Q 2: What is a latch-in cement plug?

A latch-in cement plug is used with a stab-in float collar, enabling precise placement and minimizing cement contamination.

Q 3: How does a non-rotating cement plug work?

Non-rotating plugs have anti-rotation features that lock in place during drill-out, reducing time and tool wear.

Q 4: When should I use a conventional cement plug?

Conventional cement plugs are used in standard cementing operations with float collars or shoes to seal off the casing.

Q 5: What is the difference between top and bottom cement plugs?

The bottom plug precedes the cement to wipe mud, while the top plug follows to provide pressure indication upon contact.

Q 6: Are Emson’s cementing plugs compatible with all casing sizes?

Yes, our plugs are available in sizes from 4½” to 20″ and can be customized to match specific casing dimensions.

Q 7: What material is used in cementing plugs?

Emson plugs are made from drillable rubber and aluminum or composite cores, suitable for PDC drill-outs.

Q 8: What is a PDC drillable cement plug?

A PDC drillable plug is designed to be easily drilled out using PDC bits, minimizing rig time.

Q 9: Do you supply single or double plug systems?

Yes, we offer single-plug and double-plug systems, including top and bottom plug combinations for two-stage cementing.

Q 10: Are your cement plugs API 10D compliant?

Absolutely. All our plugs are manufactured in line with API 10D standards for cementing equipment.

Q 11: Can I use non-rotating plugs in horizontal wells?

Yes, our non-rotating plugs are ideal for horizontal and extended-reach wells where efficient drill-out is critical.

Q 12: What is the pressure rating for Emson’s cementing plugs?

Our plugs are pressure-tested and rated for high-pressure well applications, depending on the plug type and well conditions.

Q 13: What is a latch-in stinger and how does it relate to cement plugs?

A latch-in stinger is used to engage the latch-in plug, ensuring accurate placement in large-diameter casing.

Q 14: How are cement plugs installed in casing?

Plugs are loaded into the cementing head and pumped downhole with displacement fluid during the cement job.

Q 15: Why choose Emson Oil Tools for cementing plugs?

Emson is a trusted cementing plug manufacturer and exporter in India, offering durable, API-certified products tailored to global well conditions.