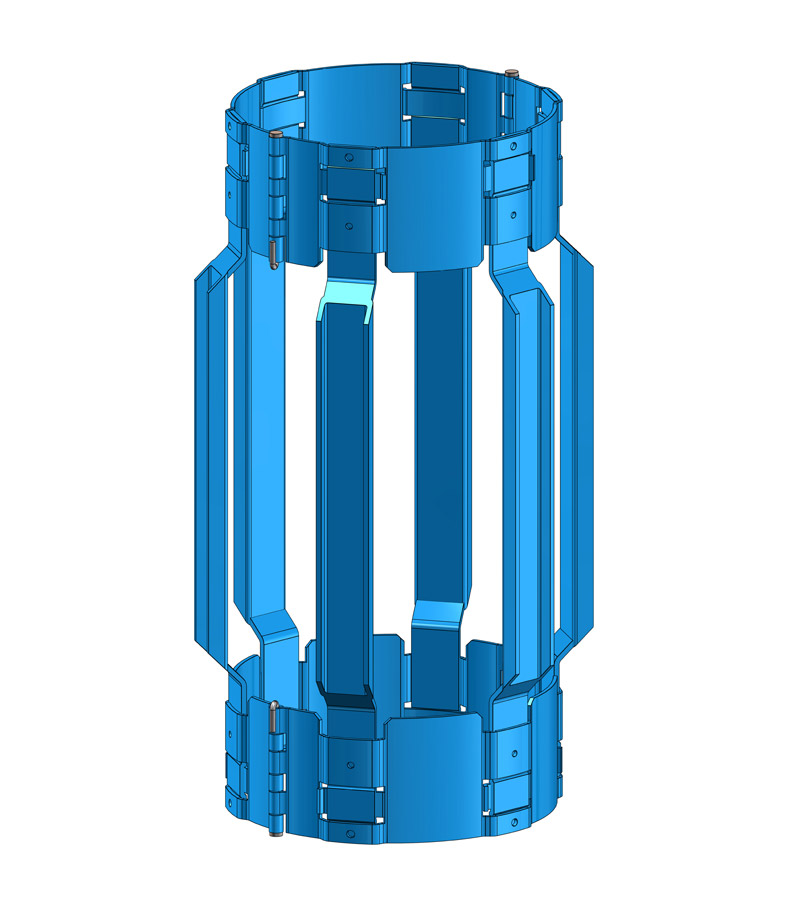

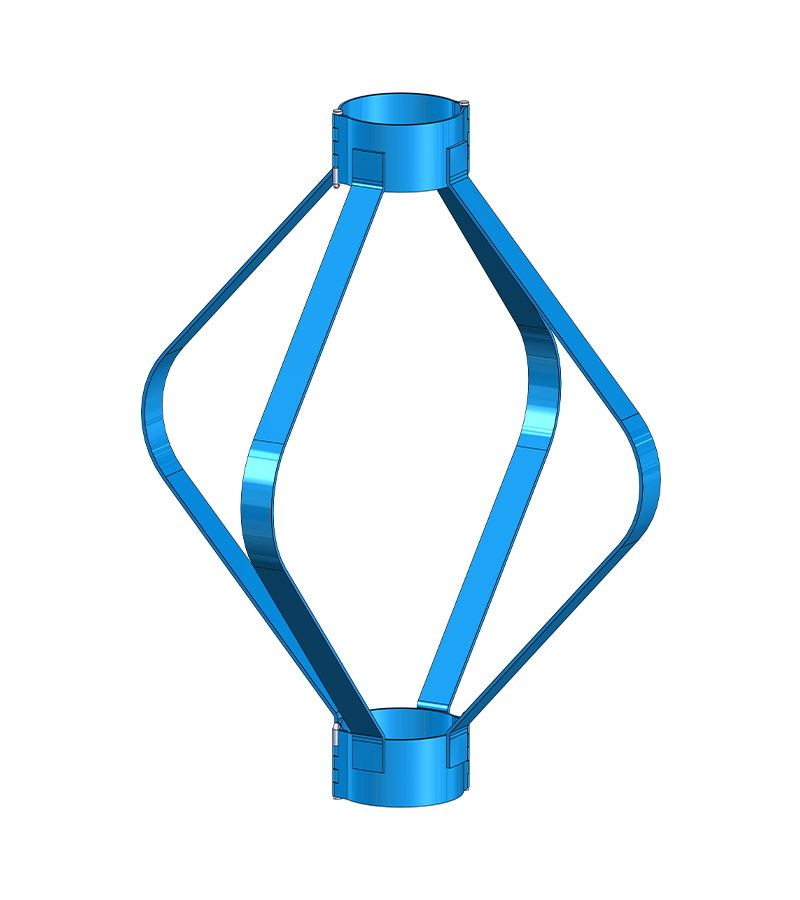

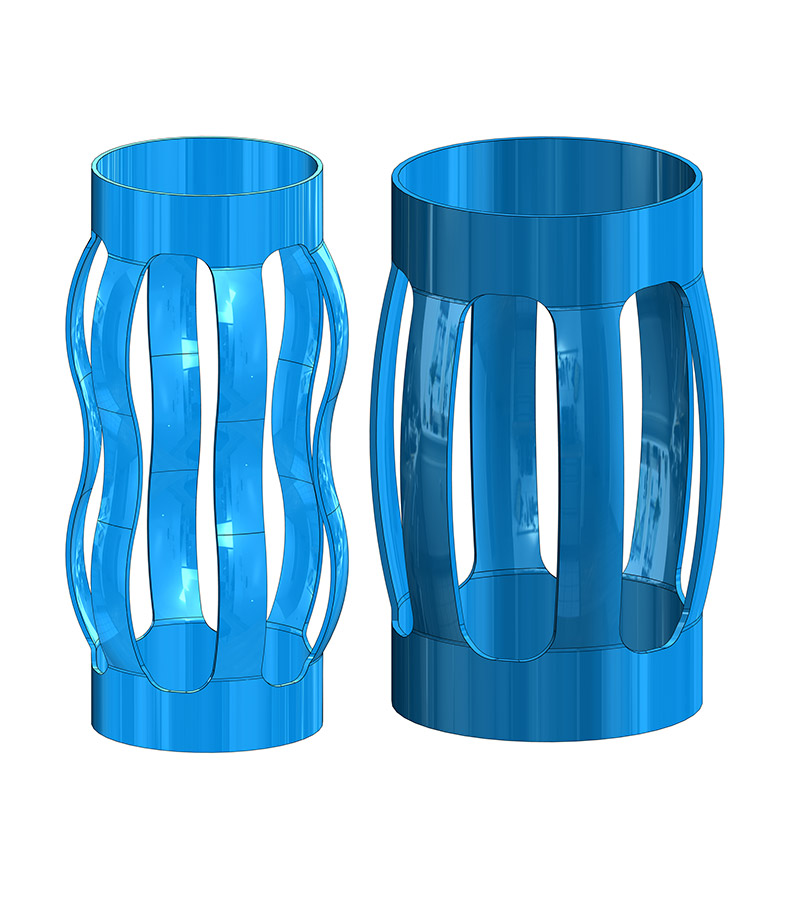

Centralizers are critical for ensuring proper casing placement and effective cementing during well construction. At Emson Oil Tools, we offer a full range of API-compliant centralizers designed for various well conditions, including Hinged Non-Welded Positive Rigid Bow Centralizers, Thermoplastic Centralizers, Drill Pipe Centralizers, Single Piece Centralizers, and Solid Body Centralizers with Spirolizers.

Our product line also includes Roller Centralizers (Low Torque & Low Drag Types), Slip-On Welded Spirolizers, Stand-Off Bands, and Solid Rigid Centralizers in aluminum, zinc, and carbon steel. These centralizers ensure casing remains centralized for uniform cement distribution, reducing the risk of channeling and improving zonal isolation.

As a leading centralizers manufacturer and exporter in India, Emson Oil Tools delivers high-performance, field-tested casing accessories that enhance well integrity and reduce operational risks in both onshore and offshore drilling environments.

Frequently Asked Questions (Faqs)

Q 1: What is a centralizer in oil and gas drilling?

A centralizer is a casing accessory that ensures the casing remains centered in the wellbore to achieve uniform cement placement.

Q 2: What types of centralizers does Emson Oil Tools offer?

We manufacture rigid bow, thermoplastic, drill pipe, solid body, roller, and single-piece centralizers, including various spirolizer models.

Q 3: When should I use a hinged non-welded bow centralizer?

Use it in wells with irregular boreholes or deviated sections, where flexibility and strong restoring force are needed.

Q 4: What are thermoplastic centralizers used for?

Thermoplastic centralizers are corrosion-resistant and lightweight, ideal for high-temperature or chemical exposure environments.

Q 5: What is a solid body centralizer?

A solid body centralizer provides maximum durability and rigidity, ensuring proper standoff in challenging formations.

Q 6: How do spirolizers improve cementing?

Spirolizers create turbulence in the annular flow, improving mud removal and cement bonding.

Q 7: What’s the difference between low torque and low drag roller centralizers?

Low torque rollers minimize resistance while rotating, whereas low drag types ease casing movement in horizontal wells.

Q 8: What is a single piece centralizer?

A single-piece centralizer is a monoblock design, offering higher strength and uniform restoring force.

Q 9: Do you offer aluminum and zinc blade centralizers?

Yes, we manufacture aluminum and zinc spiral blade solid rigid centralizers for corrosion resistance and wellbore navigation.

Q 10: Are Emson’s centralizers API certified?

Yes, all our centralizers are designed and tested in accordance with API 10D standards.

Q 11: What is a stand-off band used for?

Stand-off bands help maintain casing standoff where centralizer installation may not be practical.

Q 12: Can I use centralizers in horizontal wells?

Absolutely. We provide low drag and solid body centralizers engineered for horizontal and deviated wells.

Q 13: What sizes are available for centralizers?

Emson centralizers are available in sizes from 4½” to 20″, with customization available on request.

Q 14: How are centralizers installed on casing?

Depending on the type, centralizers are either slip-on, hinged, or bolted directly to the casing before running in hole.

Q 15: Why choose Emson Oil Tools for centralizers?

We are a leading manufacturer and exporter in India, offering durable, API-compliant, and cost-effective casing centralization solutions.