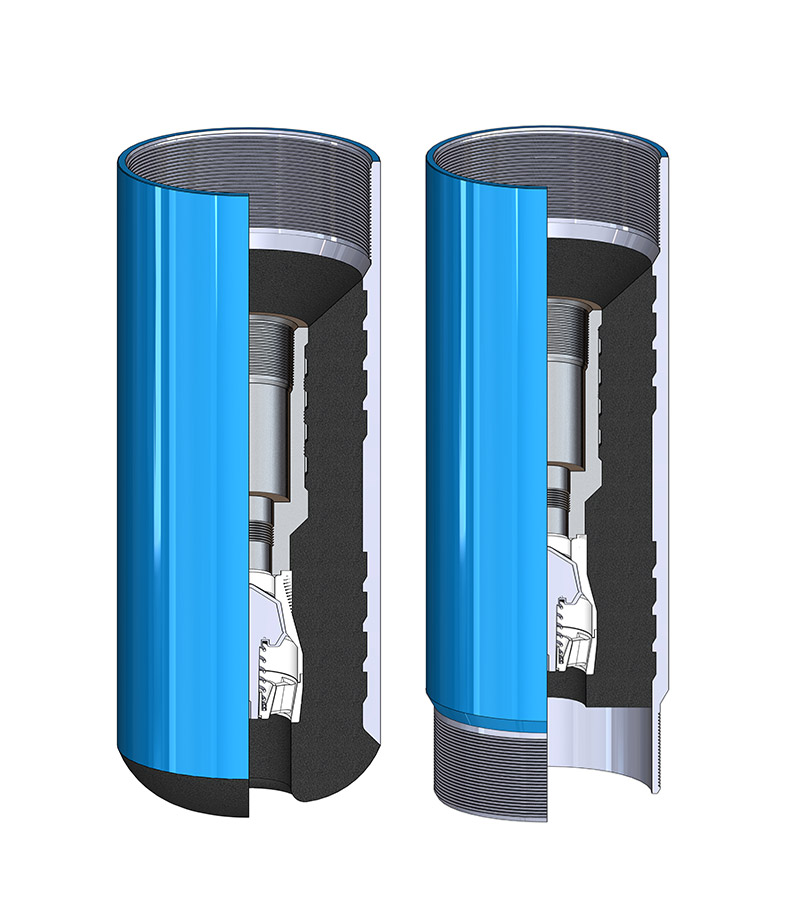

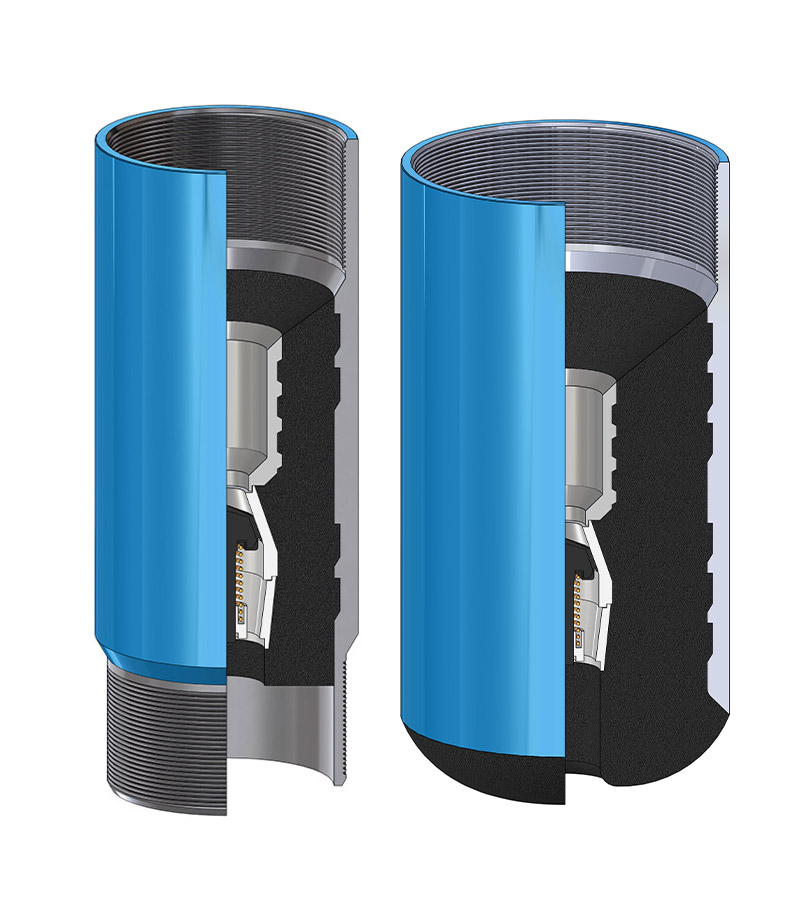

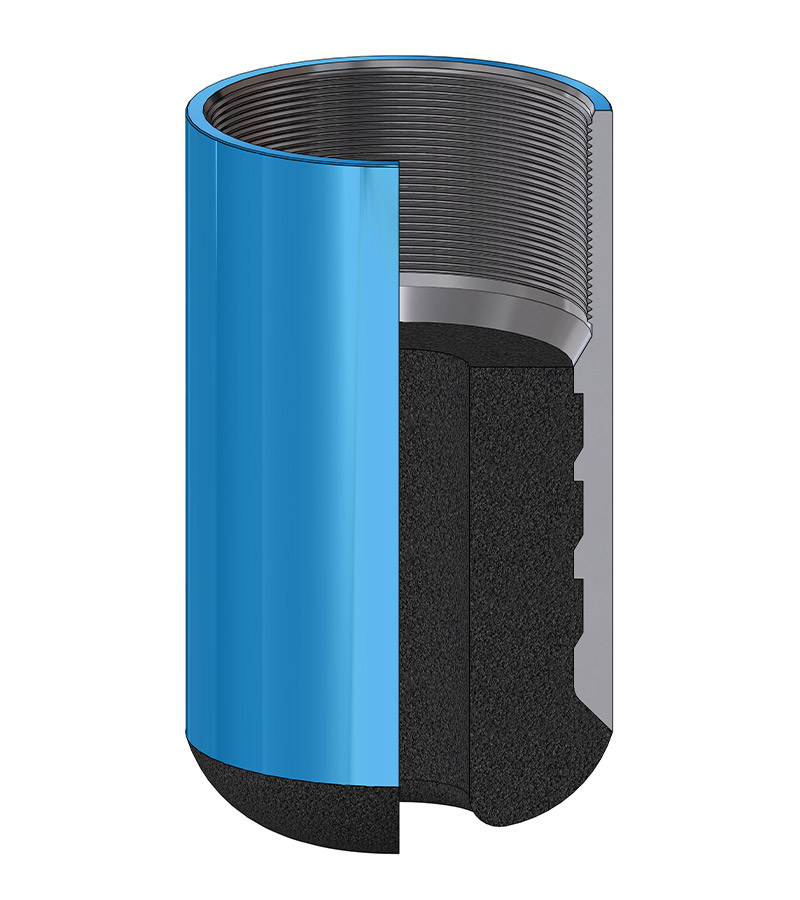

Float Equipment plays a critical role in ensuring effective cementing operations during well construction. At Emson Oil Tools, we offer a comprehensive range of high-performance Float Equipment products, including Float Shoes, Float Collars, Stab-in Float Shoes and Collars, Auto Fill Float Shoes and Collars, Stab-in Latch Stingers, Reamer Shoes, and Guide Shoes.

Whether you need a single valve or double valve float collar, a stab-in stinger for large-diameter casing, or a non-rotating float shoe for complex wells, our API-compliant equipment ensures reliable performance in high-pressure drilling conditions. Designed for both onshore and offshore applications, our float equipment guarantees backflow prevention, precise cement placement, and wellbore stability.

As a trusted manufacturer and exporter of float equipment in India, we help oilfield operators minimize cementing failures and improve zonal isolation across all well types.

Frequently Asked Questions (Faqs)

Q1: What is float equipment in oil and gas drilling?

Float equipment includes float shoes and float collars used to guide casing and prevent cement backflow during well cementing.

Q2: What are the types of float shoes available?

We offer conventional float shoes, stab-in float shoes, auto-fill float shoes, reamer shoes, and guide shoes, in single and double valve options.

Q3: When should I use a stab-in float shoe and collar?

Stab-in float shoes are ideal for large-diameter casing strings where reduced cement volume and faster installation are critical.

Q4: What is a stab-in stinger used for?

A stab-in stinger connects with the stab-in float collar or shoe for high-volume cementing without compromising displacement accuracy.

Q5: What’s the difference between conventional and non-rotating float collars?

Non-rotating float collars reduce drill-out time with anti-rotation features, while conventional float collars are more cost-effective for standard operations.

Q6: Do you provide single and double valve float shoes?

Yes, we offer both single valve and double valve float shoes and collars for enhanced well control and safety.

Q7: What is the purpose of an auto-fill float shoe?

An auto-fill float shoe allows automatic casing filling during running-in-hole, reducing rig time and hydrostatic pressure.

Q8: What is a reamer shoe used for in drilling?

A reamer shoe helps navigate tight spots and ream the hole as casing is run, especially in deviated wells.

Q9: How does a guide shoe work?

Guide shoes help the casing pass smoothly through formations, minimizing obstructions at the wellbore bottom.

Q10: Are Emson Oil Tools’ float equipment API compliant?

Yes, all float equipment is designed to meet or exceed API 10F and 5CT standards.

Q11: Can float equipment handle high-pressure wells?

Absolutely. Our float collars and shoes are engineered to perform reliably in high-pressure, high-temperature (HPHT) environments.

Q12: What sizes are available for float shoes and collars?

Our float equipment is available from 2-7/8″ to 30″, with custom sizes upon request.

Q13: Is float equipment suitable for offshore drilling?

Yes, our robust and corrosion-resistant float equipment is used in offshore and deepwater operations worldwide.

Q14: Do float collars prevent backflow?

Yes, both single and double valve float collars prevent cement from flowing back into the casing after displacement.

Q15: Why choose Emson Oil Tools for float equipment?

As a reputed float equipment manufacturer and exporter in India, we offer API-certified, durable, and field-tested products backed by reliable service.