Stop Collars for Oilfield Casing Centralization

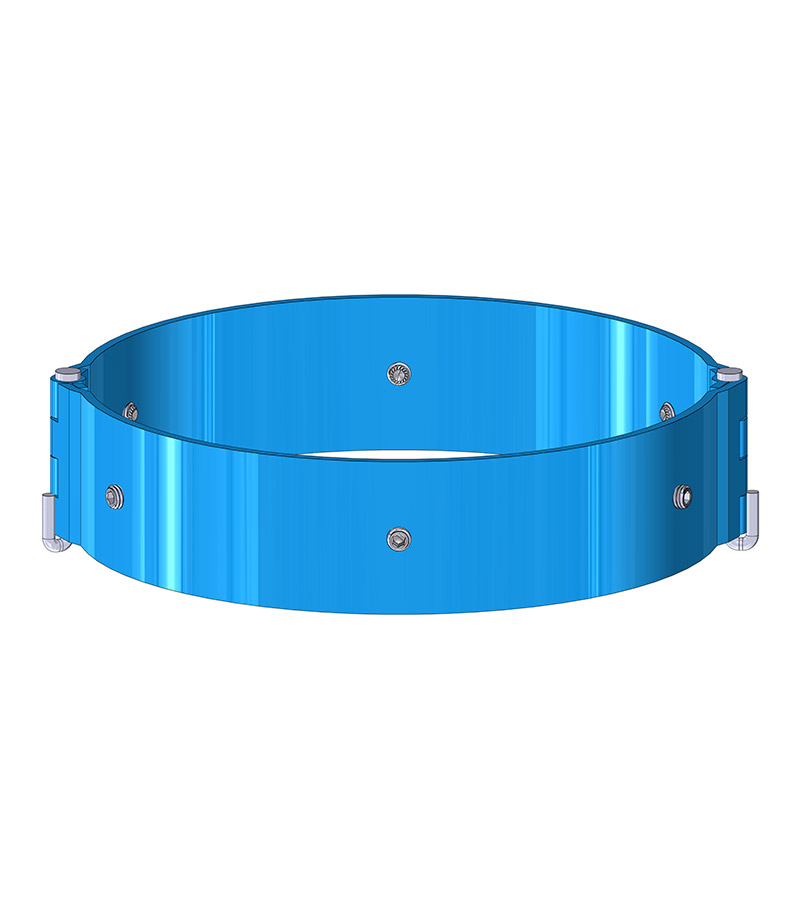

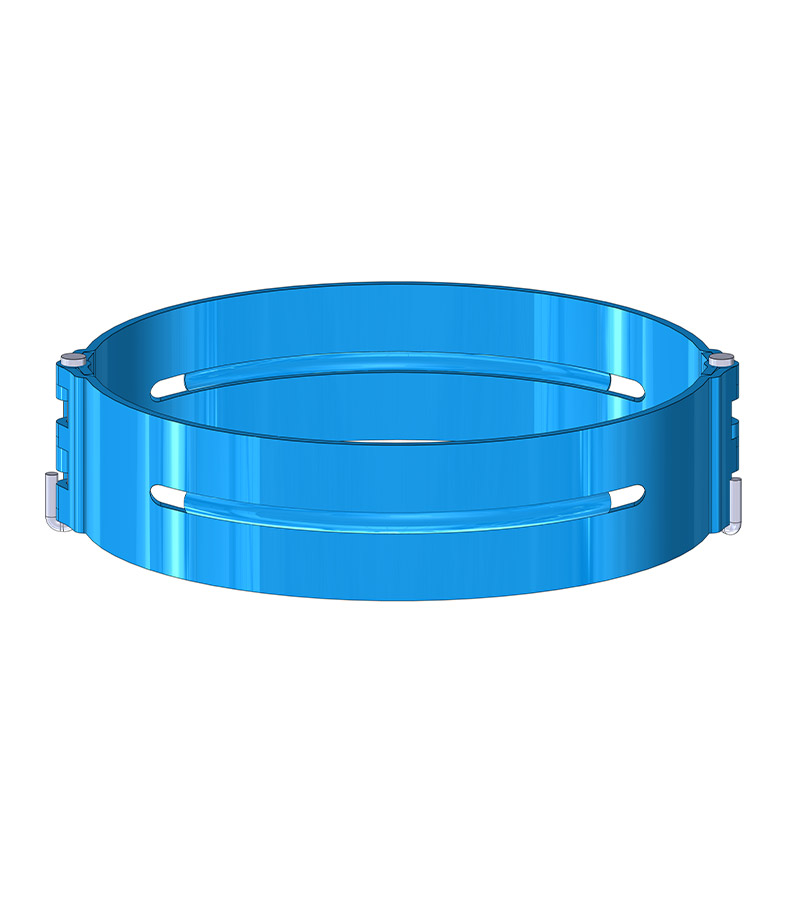

Emson Oil Tools manufactures a comprehensive range of Stop Collars designed to secure centralizers and other downhole tools at precise positions along the casing string during drilling and cementing operations. These essential casing accessories play a critical role in maintaining centralizer placement, preventing axial movement, and ensuring proper cement distribution around the casing.

Our stop collars are engineered for durability, strong holding force, and easy installation in the field. Designed to perform reliably in vertical, deviated, and horizontal wells, they help improve wellbore stability and support efficient cementing operations.

At Emson Oil Tools, we manufacture multiple types of stop collars to suit different well conditions, casing sizes, and operational requirements.

Frequently Asked Questions (Faqs)

What is a Stop Collar in Oilfield Operations?

A Stop Collar is a casing accessory used to hold centralizers, scratchers, or other downhole equipment securely in place on the casing string.

During casing running and cementing operations, stop collars prevent centralizers from sliding along the casing. This ensures proper centralization of the casing inside the wellbore, which is essential for achieving effective cement placement and long-term well integrity.

Stop collars are widely used in oil and gas drilling operations where accurate positioning of centralizers and other tools is critical to maintaining wellbore stability and cement bonding.

What is a stop collar used for in oilfield operations?

A stop collar secures centralizers and other tools at a fixed position on the casing string during running and cementing operations.

What types of stop collars are available?

Emson manufactures slip-on set screw, hinged bolted, hinged spiral nail, and hinged set screw stop collars.

What is the difference between slip-on and hinged stop collars?

Slip-on collars slide over the casing pipe, while hinged collars open and clamp around the casing for easier installation.

Are stop collars suitable for deviated wells?

Yes. Emson stop collars are designed for vertical, deviated, and horizontal well conditions.

What casing sizes do your stop collars support?

Stop collars are available for casing sizes ranging from 4½″ to 20″, with custom sizes available.